M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the integrity and safety of drilling operations by preventing uncontrolled gas or fluid releases, known as blowouts.

At M&M International, we are at the forefront of innovations in safety valve technology, continually enhancing safety standards and reliability for our clients. This blog explores the latest advancements in drill stem safety valves and highlights how M&M International is driving improvements in operational safety within the oil and gas industry.

Drill stem safety valves are essential components in drilling operations, acting as a fail-safe mechanism to control wellbore pressure and prevent blowouts. A blowout can lead to catastrophic consequences, including environmental disasters, significant financial losses, and threats to human life. Therefore, drill stem safety valves are designed to swiftly help to seal the wellbore in the event of unexpected high-pressure surges, maintaining control over the drilling environment.

The reliability of drill stem safety valves directly impacts the overall safety and efficiency of drilling operations. High-performance safety valves ensure that drilling activities can proceed without interruption, reducing downtime and minimizing risks. As the oil and gas industry continues to push the boundaries of exploration and extraction, the demand for advanced safety solutions like drill stem safety valves has never been greater.

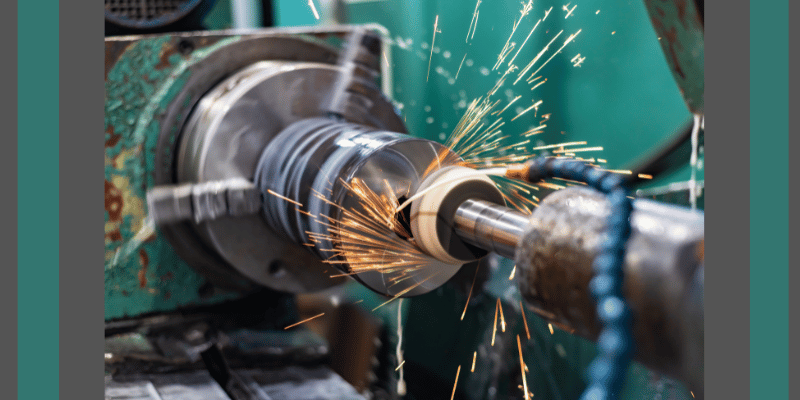

One of the most significant advancements in drill stem safety valve technology is the use of high-performance materials and innovative design principles. Modern drill stem safety valves are constructed from materials that offer superior strength, corrosion resistance, and durability. These materials ensure that the valves can withstand the extreme pressures and harsh environments typical of oil and gas drilling operations.

Innovative design features, such as streamlined geometries and optimized flow paths, enhance the performance and reliability of drill stem safety valves. These design improvements reduce the likelihood of mechanical failures and ensure that the valves can respond swiftly and effectively in emergency situations.

Effective sealing is crucial for the functionality of drill stem safety valves. Recent innovations in sealing technologies have significantly improved the ability of safety valves to maintain a secure seal under high-pressure conditions. Advanced sealing materials and designs provide better resistance to wear and tear, extending the lifespan of the valves and ensuring consistent performance.

At M&M International, we incorporate state-of-the-art sealing solutions that enhance the reliability of our drill stem safety valves. These advanced seals prevent leaks and ensure that the valves can perform their critical safety functions without compromise.

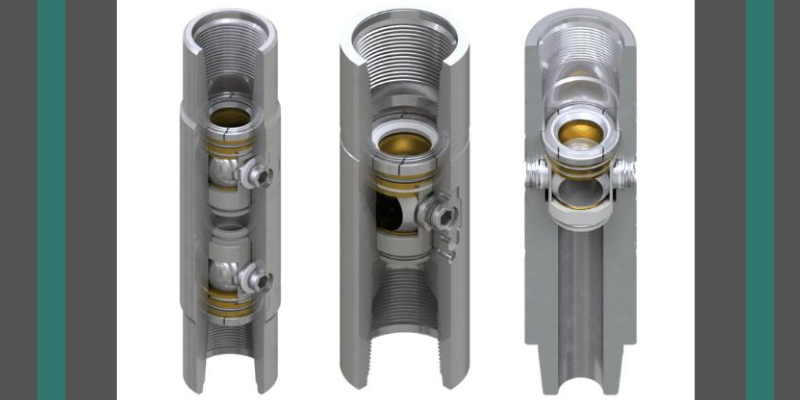

M&M International’s patented CANISTER GUARD® technology is a game-changer in the realm of drill stem safety valves. This innovative system integrates modular internal components, allowing for easier maintenance and reduced downtime. The CANISTER GUARD® encapsulates internal spring loading within the canister, eliminating common issues associated with traditional valve designs, such as debris accumulation and corrosion.

By simplifying the disassembly and reassembly processes, CANISTER GUARD® technology ensures that our drill stem safety valves remain operationally reliable and easy to service, even in the most challenging drilling environments.

M&M International leads the industry with our proprietary CANISTER GUARD® technology, which significantly enhances the functionality and maintenance of drill stem safety valves. This patented innovation sets us apart by offering superior performance, ease of maintenance, and extended valve longevity. Our commitment to developing cutting-edge technologies ensures that our drill stem safety valves meet the highest safety and reliability standards.

Quality control is at the heart of our manufacturing process. Each drill stem safety valve undergoes comprehensive testing and inspection to verify its performance and reliability. We employ advanced quality control inspection techniques, including Coordinate Measuring Machines (CMM) and Optical Comparators, to ensure that every component meets exacting specifications.

Our rigorous quality assurance protocols guarantee that M&M International’s drill stem safety valves perform flawlessly in the field, providing our clients with the confidence and security they need in their drilling operations.

Understanding that every drilling operation has unique requirements, M&M International offers customized drill stem safety valve solutions tailored to meet specific client needs. Our engineering team collaborates closely with clients to design and manufacture safety valves that address their operational challenges and enhance overall safety.

By providing bespoke solutions, we ensure that our drill stem safety valves deliver optimal performance and reliability, further solidifying M&M International’s reputation as a trusted leader in oil and gas safety technologies.

The continuous advancements in drill stem safety valve technology significantly mitigate the risks associated with drilling operations. Enhanced materials and designs increase the resilience of safety valves, reducing the likelihood of mechanical failures and ensuring that the valves can perform effectively under extreme conditions.

Improved sealing technologies enhance the operational reliability of drill stem safety valves. The integration of CANISTER GUARD® technology streamlines maintenance processes, ensuring that safety valves remain in optimal condition with minimal downtime.

These innovations not only enhance the safety and efficiency of drilling operations but also provide substantial cost savings by reducing the need for extensive maintenance and minimizing the impact of potential blowouts. By investing in advanced drill stem safety valve technologies, M&M International helps clients achieve safer, more reliable, and more efficient drilling operations.

Innovations in drill stem safety valves are transforming the landscape of operational safety in the oil and gas industry. At M&M International, we are dedicated to pushing the boundaries of drill stem safety valve technology, ensuring that our valves provide unparalleled safety, reliability, and performance. Our commitment to advanced materials, innovative designs, and rigorous quality assurance processes sets us apart as a leader in enhancing operational safety for drilling operations.

By leveraging these cutting-edge advancements, M&M International not only reduces the risks associated with drilling but also improves the overall reliability and efficiency of our clients’ operations. Trust in M&M International to deliver superior drill stem safety valves that safeguard your operations and drive success in the dynamic oil and gas industry.

Contact us today to learn more about our innovative drill stem safety valve solutions and how we can support your operational safety needs.

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

In the oil and gas industry, well control is a critical aspect of ensuring safe and efficient operations. One of the most crucial components in...

Inside Blow-Out Preventers (IBOPs) are critical safety components in the oil and gas industry, designed to provide a fail-safe mechanism for...

With a rich heritage spanning decades, M&M International has been at the forefront of crafting upper and lower top drive valves. Engineered...