M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Aug 28, 2024 2:42:53 PM

M&M International

Aug 28, 2024 2:42:53 PM

The manufacturing landscape is constantly advancing, and two fundamental processes—cold rolling and hot rolling—remain at the core of metal fabrication. These techniques are pivotal in shaping the properties and applications of metal products.

In this blog post, we delve into the differences between cold rolling and hot rolling, examining their mechanical characteristics, the impact on material properties, and how each method suits different manufacturing applications. Understanding these processes is essential for selecting the right approach to meet specific engineering and production needs.

Cold rolling involves passing the metal through rollers at a temperature below its recrystallization point, typically at or near room temperature. This process requires more force due to the hardness of the metal at lower temperatures.

Cold rolled steel offers several advantages that make it a preferred choice for various applications. One of the primary benefits is its superior surface finish, which is smooth and polished, making it ideal for products where appearance is important, such as home appliances, automotive body panels, and furniture.

Additionally, the cold rolling process increases the steel’s strength and hardness through strain hardening, making it suitable for applications that require high tensile strength and durability, such as in construction components, precision tools, and machinery parts.

The enhanced dimensional accuracy and tighter tolerances achieved with cold rolled steel also make it an excellent choice for manufacturing intricate components that demand precision, such as electronics and metal containers. These advantages, combined with its versatility, make cold rolled steel a vital material in industries ranging from oil and gas to automotive and consumer goods.

Hot rolling is a metalworking process where the metal is heated above its recrystallization temperature and then passed through rollers to achieve the desired thickness. The high temperature allows the metal to be easily shaped and formed, reducing the risk of fractures during rolling.

Hot rolled steel offers several advantages, making it ideal for a wide range of applications. One of the primary benefits is its cost-effectiveness; because the steel is processed at high temperatures, it is easier to shape and form, which reduces production time and costs.

Additionally, hot rolled steel has excellent ductility and toughness, making it well-suited for applications that require strong, flexible materials, such as construction beams, railroad tracks, and automotive frames.

Its ability to withstand significant stress and strain without breaking makes it a reliable choice for structural components where durability is crucial. Although it may have a rough surface finish, this can be easily addressed with additional treatments, depending on the specific requirements of the project.

The primary difference between hot rolling and cold rolling lies in the temperature at which these processes occur. Hot rolling involves processing the metal above its recrystallization temperature, making the material more malleable and easier to shape. In contrast, cold rolling is performed at or near room temperature, resulting in steel with higher strength and hardness.

However, it’s important to understand that these techniques are about the rolling process itself and should not be confused with the formal specifications or grades of steel, which pertain to metallurgical composition and performance characteristics. Both basic carbon steels and various alloy steels can be hot rolled or cold rolled, depending on the desired properties.

When considering the application of these processes, surface quality and material hardness are key factors. Hot rolled steel typically has rougher edges and surfaces that may require additional treatments like decarburization before further processing. On the other hand, cold rolled steel usually boasts a smoother, shinier surface that can often be used directly in production.

The cold rolling process also enhances the material's strength and hardness but introduces greater internal stresses, which must be relieved to avoid issues like warping in the final product. Choosing the appropriate rolling process for a project is essential, as it impacts not only the material properties but also the overall cost and efficiency of production. Understanding these differences helps in selecting the right type of steel for specific applications, ultimately saving time and resources.

In manufacturing engineering, the choice between cold rolling and hot rolling depends on the specific requirements of the application.

The future of metal fabrication is being shaped by the critical processes of cold rolling and hot rolling, each playing a vital role in manufacturing engineering. At M&M International, we recognize the importance of these techniques in delivering high-quality metal products tailored to the unique needs of our clients.

As we continue to innovate and refine our manufacturing capabilities, M&M International remains committed to leveraging these processes to meet the evolving demands of the industry. Our expertise ensures that we can offer the most effective solutions for your metal fabrication needs. Contact us for more information or to get a quote on your hot or cold rolling needs.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

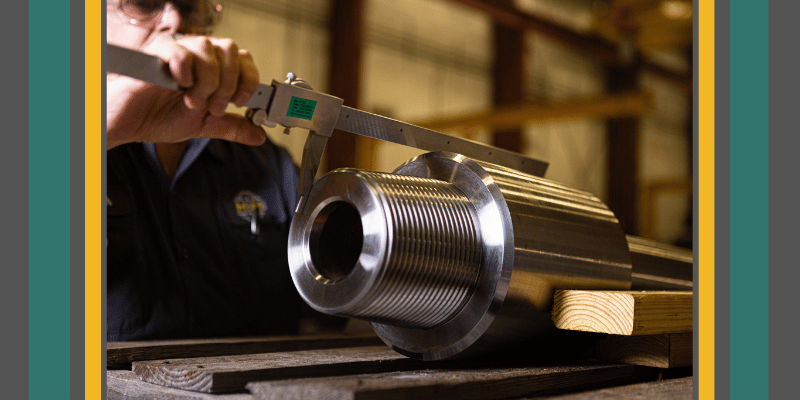

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

In the dynamic and high-stakes world of oilfield equipment manufacturing, precision, quality, and reliability are non-negotiable. Among the array of...

In the complex field of manufacturing engineering, quality control inspections are not just a procedural formality—they are a fundamental...

In the oil and gas industry, well control is a critical aspect of ensuring safe and efficient operations. One of the most crucial components in...