M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Sep 4, 2024 9:06:18 AM

M&M International

Sep 4, 2024 9:06:18 AM

In the realm of manufacturing engineering, the phosphating process stands out as a critical technique for enhancing the durability and performance of metal components. This introductory guide delves into the phosphating process, exploring how it works, its various applications, and the significant benefits it offers in protecting metals from corrosion and improving paint adhesion.

Phosphating, also known as phosphate coating, is a chemical treatment applied to metal surfaces to enhance their resistance to corrosion, improve anti-friction properties, and provide a better surface for paint adhesion. This process involves the formation of a layer of phosphate crystals on the metal substrate through a reaction with a phosphoric acid solution. The result is a protective coating that not only prevents rust but also prepares the surface for subsequent coatings.

The phosphating process offers several advantages:

The phosphating process begins with the preparation of the metal surface, which is typically cleaned to remove any dirt, oil, or rust. This is followed by immersing the metal in a phosphating solution, which contains phosphoric acid along with other chemicals. During the treatment, the phosphoric acid reacts with the metal, typically steel or iron, forming a layer of iron phosphate or zinc phosphate.

The coating thickness and structure depend on factors such as the composition of the phosphating solution, the temperature, and the treatment time. This layer of phosphate crystals acts as a protective barrier against environmental factors that cause corrosion, as well as offering protection against galling. Additionally, the porous nature of the coating provides an excellent base for the application of paints and other finishes.

Phosphating is widely used across various industries due to its versatility and effectiveness. Some common applications include:

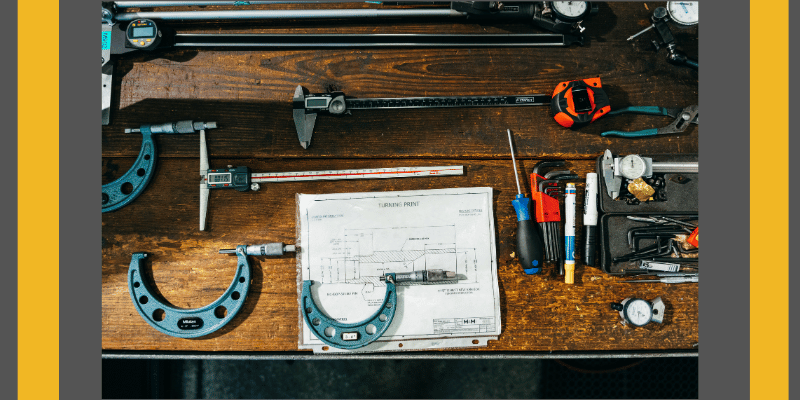

From an engineering perspective, phosphating involves a careful balance of chemistry and process control. The formulation of the phosphating solution, the precise control of temperature and timing, and the method of application all play crucial roles in achieving the desired coating properties. Modern manufacturing settings leverage advanced techniques and equipment to optimize the phosphating process, ensuring consistent quality and performance.

M&M International is lauded over and over again by customers and vendors alike for the outstanding results of our phosphating method. The high-quality result of our proprietary recipe, or our “secret sauce” if you will, is the envy of other manufacturers who provide phosphating services. We have perfected our method over many years, and its sleek black finish, combined with the other benefits discussed in this guide, make it the best in class phosphate coating that it is.

Engineering is integral to the phosphating process, impacting every stage from chemical formulation to the final application on metal components. Engineers carefully design the phosphating solution, balancing the mix of chemicals like phosphoric acid and metal salts to create a consistent, protective layer. They also establish and control key process parameters such as temperature, pH levels, and solution concentration, ensuring that the coating is uniform and meets the desired specifications.

Beyond chemical formulation, engineering decisions drive the selection of application methods—whether immersion, spraying, or another technique—based on the specific characteristics of the metal components and the scale of production. Engineers also design and select equipment that maintains precise control over the process conditions, ensuring consistent quality and optimizing efficiency. With the help of real-time monitoring systems and automation, engineers can dynamically adjust process parameters to prevent defects and improve repeatability.

Quality assurance and continuous improvement are also major engineering contributions to phosphating. Engineers develop methods to test the coating’s quality, assessing factors like thickness, uniformity, and adhesion to ensure it meets necessary standards. They also focus on optimizing the process through analysis and testing, making adjustments to improve performance.

Additionally, engineering plays a vital role in addressing environmental and safety concerns, designing systems for waste management and ensuring the process is conducted safely. Engineers also ensure that phosphating integrates seamlessly with other manufacturing processes, maintaining production flow and meeting overall manufacturing goals.

In today's manufacturing landscape, where quality and durability are paramount, phosphating remains a vital process. Its ability to enhance metal protection and improve paint adhesion makes it indispensable across various sectors. By understanding and utilizing the phosphating process, manufacturers can ensure the longevity and reliability of their products, meeting the demands of both traditional and emerging markets.

The future of metal working is also being shaped by the critical process of phosphating, a cornerstone of modern manufacturing engineering. At M&M International, we understand the vital role that phosphating plays in enhancing corrosion protection, galling prevention, and paint adhesion, ensuring the durability and performance of metal components.

As we continue to refine our manufacturing capabilities, as well as our "secret sauce", M&M International remains dedicated to integrating phosphating into our processes to meet the evolving demands of the industry. Our unrivaled expertise in this essential technique allows us to offer the most effective solutions for your metal working needs. Contact us today!

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

There are various types of subs used in drilling, but one of the most crucial is the crossover sub. Let's examine the significance of this sub and...

Precision and efficiency are critical in producing industrial valves, where even the smallest error can impact performance. M&M International stands...

At M&M International, our commitment to excellence in mechanical engineering is foundational to our success in delivering high-performance valves....