M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Jun 21, 2024 3:08:17 PM

M&M International

Jun 21, 2024 3:08:17 PM

In the manufacturing and industrial sectors, the functionality and reliability of equipment are paramount. One of the key components that ensure smooth operation in various systems is the swivel. Swivels are critical in numerous applications, from loading arms to hydraulic systems. At M&M International, we understand the importance of these components in optimizing performance and enhancing safety. In this blog post, we'll explore various types of swivels, including their applications and benefits.

In the world of manufacturing, few components are as versatile and essential as swivels. Whether in industrial machinery, office furniture, or everyday household items, swivels play a critical role in ensuring smooth and efficient movement. But what exactly are swivels, and why are they so important?

Swivels are mechanical devices that allow an object to rotate freely in one or more directions. This rotational capability is achieved through a connection, often a ball bearing, that enables 360-degree movement. Swivels can be found in a wide range of applications, from the flexible neck of a desk lamp to the rotating wheels of a shopping cart. Their ability to facilitate rotation without transferring significant load or stress to the connected parts makes them indispensable in various engineering and design contexts.

In this blog post, we'll delve into the fascinating world of swivels, exploring their different types, functions, and the critical role they play in modern manufacturing. Whether you're an engineer, designer, or simply curious about the mechanics behind everyday objects, this introduction to swivels will provide you with a deeper understanding of their importance and applications.

Loading arm replacement swivels are essential for the efficient transfer of liquids and gases in industrial settings. These swivels are designed to facilitate the smooth and safe movement of loading arms, which are used in the transfer of hazardous and non-hazardous materials. They ensure flexibility and prevent hose kinks and twists, which can lead to operational delays or accidents. Commonly used in the petrochemical, oil, and gas industries, loading arm replacement swivels are a cornerstone in maintaining safety and efficiency.

Applications include:

Hose reel swivels are vital for maintaining the functionality of hose reels, which are used to store and deploy hoses efficiently. These swivels allow the hose to rotate without twisting, ensuring a smooth operation. In manufacturing environments where hoses are frequently extended and retracted, hose reel swivels provide the durability and flexibility needed to prevent hose damage and improve longevity.

Applications include:

Hydraulic swivels are crucial components in hydraulic systems, allowing the transfer of hydraulic fluid between stationary and rotating parts. These swivels ensure that machinery and equipment can move freely without the risk of hose twisting and tangling. In manufacturing, construction, and agricultural industries, hydraulic swivels are essential for maintaining the efficiency and reliability of hydraulic-powered equipment.

Applications include:

Dual split flange swivels are designed to offer a secure connection while allowing rotational movement in piping systems. These swivels are particularly useful in high-pressure applications where maintaining a tight seal is crucial. They provide the flexibility needed to accommodate movement and alignment adjustments without compromising the integrity of the connection.

Applications include:

Coaxial swivels are designed to allow fluid transfer through concentric passages within a single swivel joint. This design is particularly beneficial in applications where space is limited, and a compact solution is required. Coaxial swivels are commonly used in robotics, medical devices, and precision manufacturing, where efficient and precise fluid transfer is essential.

Applications include:

Side port swivels offer the advantage of having multiple connection points, providing versatility in fluid routing and system design. These swivels are ideal for applications where multiple hoses or pipes need to be connected to a single swivel joint, allowing for efficient fluid distribution and system integration.

Applications include:

Diverters are specialized swivels designed to control and direct the flow of fluids within a system. They are used to switch fluid paths, allowing for efficient management of fluid distribution. In manufacturing and industrial processes, diverters are essential for optimizing fluid flow and ensuring that systems operate smoothly and efficiently.

Applications include:

Selecting the appropriate swivel for your application can seem daunting given the variety of options available, from loading arm replacement swivels to diverters. The key to making the right choice lies in understanding the specific demands of your project. Consider the type of movement required, the load capacity, and the environmental conditions.

For heavy-duty tasks, hydraulic or dual split flange swivels might be the most suitable due to their robust construction and ability to handle high pressures. In contrast, hose reel swivels and coaxial swivels are ideal for applications requiring smooth fluid transfer with minimal resistance. Side port swivels offer versatile connection points, making them perfect for complex systems needing multi-directional flow, while diverters excel in systems where redirecting flow is essential.

Ultimately, the right swivel will not only meet the mechanical and operational requirements of your application but also enhance its efficiency and longevity. By carefully assessing these factors, you can ensure that your choice of swivel contributes to the optimal performance and reliability of your equipment.

Swivels play a pivotal role in a wide range of industrial applications, ensuring the smooth operation and reliability of various systems. At M&M International, we are committed to providing high-quality swivels that meet the specific needs of our clients in the manufacturing and industrial sectors.

By understanding the different types of swivels and their applications, you can make informed decisions to enhance the efficiency and safety of your operations. Let M&M International be your go to for all your swivel needs! Contact us today to get a quote!

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

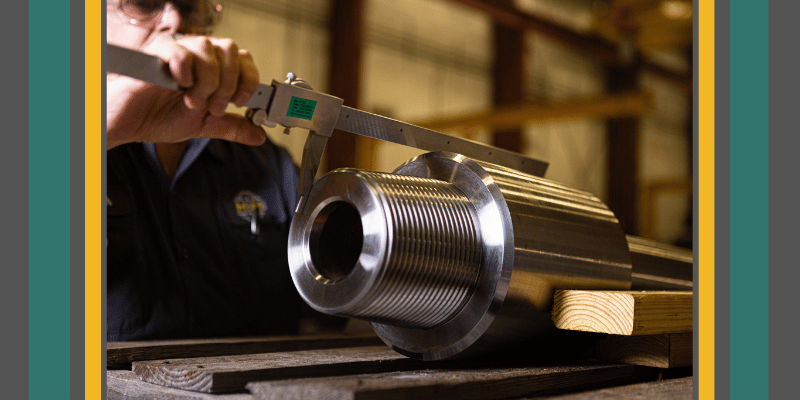

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

In the complex field of manufacturing engineering, quality control inspections are not just a procedural formality—they are a fundamental...

Inside Blow-Out Preventers (IBOPs) are critical safety components in the oil and gas industry, designed to provide a fail-safe mechanism for...

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan