M&M International Welcomes QM as Partner in Argentina

M&M International Welcomes QM as New Authorized Repair Facility (ARF) and Distributor in Argentina.

Inside Blow-Out Preventers (IBOPs) are critical safety components in the oil and gas industry, designed to provide a fail-safe mechanism for preventing blowouts during drilling operations. This blog explores the design, function, and importance of IBOPs, highlighting how M&M International integrates advanced technology and engineering expertise to ensure operational safety and efficiency.

Inside Blow-Out Preventers (IBOPs) are specialized valves installed within the drill string that can rapidly close off the well in the event of unexpected high-pressure releases or "blowouts." Their primary function is to maintain control of the wellbore pressure by sealing the inside of the drill pipe, preventing the catastrophic consequences of blowouts, including environmental damage and loss of life.

IBOPs are engineered with several features that make them indispensable in modern drilling:

IBOPs are integral to maintaining safety standards in drilling operations, playing a critical role in the prevention of blowouts—among the most perilous and financially draining challenges in drilling. These devices ensure a robust sealing mechanism within the drill string, effectively averting uncontrolled fluid discharges that can lead to operational catastrophes.

IBOPs also deliver substantial environmental protection benefits by preventing the release of harmful pollutants into the environment, a vital consideration for both offshore and onshore drilling operations. Their ability to maintain operational continuity is equally important; by eliminating the risk of blowouts, IBOPs minimize costly downtime and ensure that drilling activities progress efficiently and without interruption.

At M&M International, we incorporate cutting-edge technology and rigorous testing protocols to ensure our IBOPs meet the highest standards of quality and reliability:

Inside Blow-Out Preventers are essential for the safety and efficiency of drilling operations. M&M International’s focus on continuous innovation and quality assurance in the development of IBOPs reflects our dedication to advancing drilling safety and operational excellence, thereby supporting our clients’ needs for reliable and effective drilling solutions. In support systems such as hydraulic control circuits, gear pumps play a crucial role by providing steady, high-pressure fluid flow to activate safety devices like IBOPs. Their compact, dependable design ensures fluid movement remains consistent, even under extreme drilling conditions.

We invite you to explore more about our advanced safety solutions and how they can benefit your operations. Trust in M&M International for drilling safety technologies that lead the industry in reliability and innovation.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventers (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International Welcomes QM as New Authorized Repair Facility (ARF) and Distributor in Argentina.

M&M International Announces KLX Energy Services, LLC in Bridgeport, as New Authorized Repair Facility.

M&M International is proud to announce that it is a licensed manufacturer of Hilong’s HLST® and HLIST® super high‑torque, double‑shoulder...

There are various types of subs used in drilling, but one of the most crucial is the crossover sub. Let's examine the significance of this sub and...

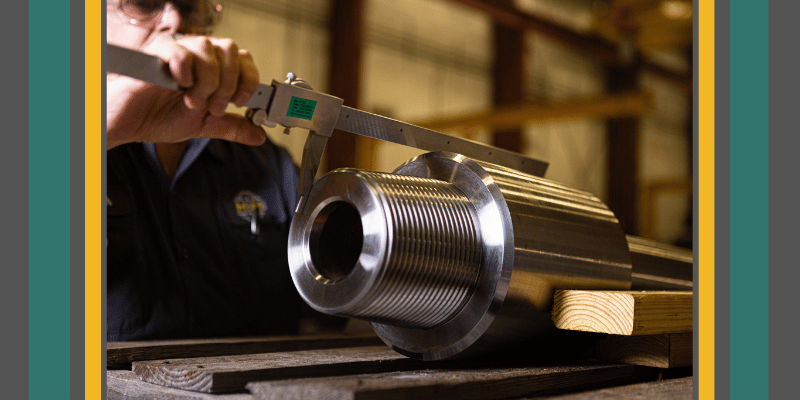

In the complex field of manufacturing engineering, quality control inspections are not just a procedural formality—they are a fundamental...

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...