M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

5 min read

%20(3).png) M&M International

Aug 5, 2024 9:47:02 AM

M&M International

Aug 5, 2024 9:47:02 AM

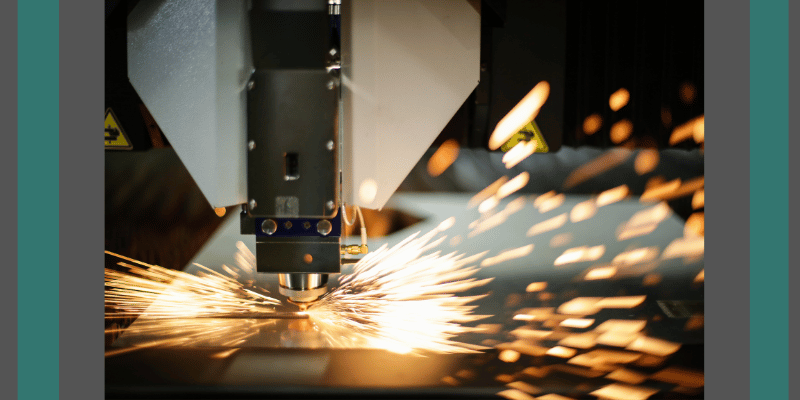

In the critical field of safety valve manufacturing, precision, traceability, and adherence to rigorous industry standards are paramount. Among the cutting-edge technologies revolutionizing this sector, laser etching emerges as a crucial tool. By enabling precise and permanent markings, laser etching enhances traceability, ensures stringent quality assurance, and facilitates compliance with industry standards, solidifying its pivotal role in safeguarding reliability and safety across all valve applications.

Laser etching is a process that uses a focused beam of light (a laser) to alter the surface of a material. This alteration can create text, barcodes, logos, or other designs with high precision. Unlike other marking methods, laser etching does not require physical contact with the material, which eliminates the risk of wear and tear on the marking tools and ensures consistent results.

The laser etching process involves directing a high-energy laser beam onto the surface of the material. The energy from the laser heats the material, causing it to vaporize or melt slightly, which creates a permanent mark. The depth and appearance of the etching can be controlled by adjusting the laser's power, speed, and focus.

Let's look at the process and how laser etching works:

In the manufacturing of safety valves, precision and reliability are crucial. Laser etching has emerged as a superior technology for marking safety valves, offering a range of benefits that enhance traceability, quality assurance, and compliance with industry standards. Let's explore the key advantages of using laser etching in this critical industry.

Traceability is essential in safety valve manufacturing to ensure that each valve can be tracked throughout its lifecycle. Laser etching provides a permanent and precise method for marking valves with crucial information, such as:

These permanent markings are resistant to wear and environmental factors, ensuring they remain legible throughout the valve component's service life. This level of traceability facilitates efficient tracking and accountability, which is vital for maintaining the integrity of the supply chain and ensuring the reliability of safety valves in critical applications.

In the manufacturing of safety valves, the type of laser commonly used for etching is the fiber laser. Fiber lasers are highly regarded for their precision, efficiency, and suitability for marking metals, which are the primary materials used in safety valve components.

This is why fiber lasers are often the preferred choice for this specific application:

Fiber lasers operate by using an optical fiber as the gain medium. The process involves the following steps:

This technology allows for precise control over the laser beam, enabling fine etching with minimal thermal impact on the material being marked.

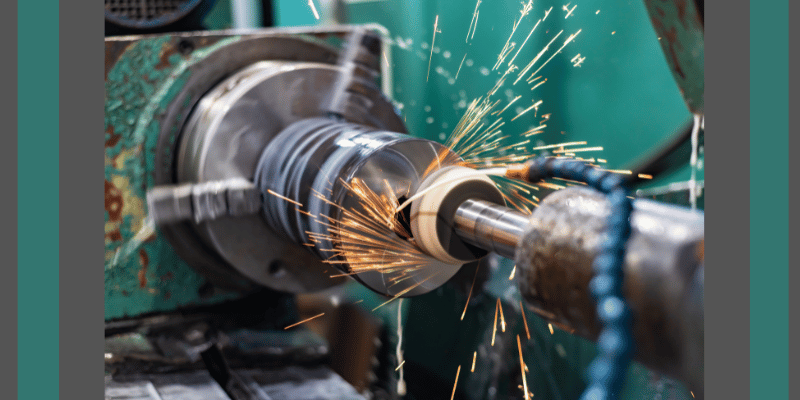

Quality assurance is at the heart of safety valve manufacturing. Ensuring that each valve meets the highest standards of quality and performance is essential to prevent failures that could lead to catastrophic consequences. Laser etching contributes to quality assurance by providing a method for precise and repeatable marking of valve components.

Unlike traditional marking methods, such as ink stamping or engraving, laser etching offers unparalleled precision. The high-resolution markings created by lasers do not compromise the structural integrity of the valve component, ensuring that the components remains robust and reliable. Furthermore, laser etching allows for intricate designs and small text, making it possible to include detailed information on even the smallest valve component.

Safety valve manufacturers must adhere to strict industry standards to ensure their products are safe and reliable. Laser etching helps manufacturers meet these requirements by providing a clear and permanent method for marking valve components with necessary information.

Laser etching can accurately and indelibly apply this information, ensuring that each valve complies with the relevant standards. This not only facilitates compliance but also enhances the confidence of end-users in the safety and performance of the valves.

The use of laser etching in the manufacturing of safety valves offers numerous benefits that enhance traceability, quality assurance, and compliance with industry standards. At M&M International, we leverage this advanced technology to provide precise, permanent, and detailed markings, ensuring that each safety valve component can be accurately tracked and identified throughout its lifecycle. This approach not only improves the reliability and safety of our valves but also contributes to the efficiency and cost-effectiveness of our manufacturing process.

As the safety valve industry continues to evolve, M&M International remains at the forefront by embracing cutting-edge technologies like laser etching. By prioritizing precision and traceability, we ensure that our safety valves meet the increasing demands for high-quality and compliant products. Contact us today to get a quote!

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

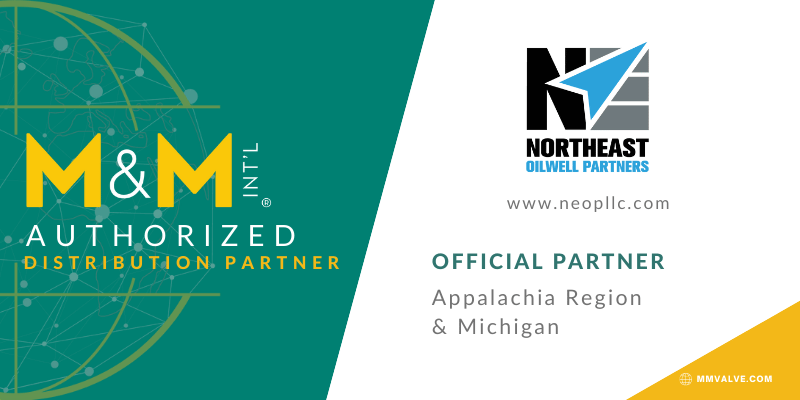

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

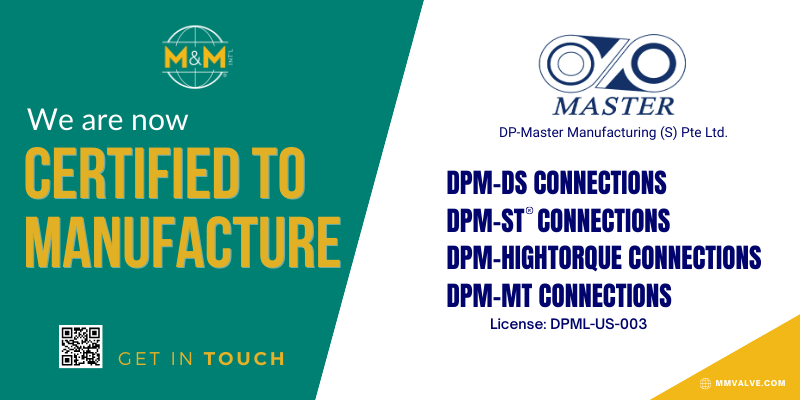

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

Precision and efficiency are critical in producing industrial valves, where even the smallest error can impact performance. M&M International stands...

Operating in the demanding oil and gas exploration field leaves no room for error. Precision isn’t just a requirement—it’s the backbone of safety,...

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...