M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Jul 15, 2024 12:26:33 PM

M&M International

Jul 15, 2024 12:26:33 PM

At M&M International, our commitment to exceptional service drives us to continuously innovate and improve. In this blog, we delve into one of the key components of our service excellence: Authorized Repair Facilities (ARFs). As a dynamic, customer-focused company, we recognize the importance of addressing both routine and complex challenges effectively.

Our ARFs play a crucial role in ensuring that our clients receive timely, proficient support and solutions, elevating the standard of service we provide beyond that of our competitors.

An Authorized Repair Facility (ARF) is a service center that has been officially certified and endorsed by M&M International to perform maintenance and repair on M&M International products.

These facilities meet stringent standards and guidelines set by M&M International to ensure high-quality workmanship and the use of genuine OEM parts. They are staffed with trained technicians and have access to specialized tools, equipment, and proprietary information necessary to carry out repairs according to M&M International's own precise specifications, as well as accepted industry standards.

The establishment of an Authorized Repair Facility ensures that customers have access to local expertise for the maintenance and repair of M&M International's products. By having a repair facility nearby, customers benefit from reduced logistical challenges/cost and faster service turnaround, ensuring their operations remain efficient and productive. Our local presence also allows us to foster closer relationships with our customers, providing them with personalized support and immediate access to the high-quality service that M&M International is known for.

The process of a quality control inspection at an Authorized Repair Facility typically involves several key steps to ensure that repairs meet established standards and regulatory requirements. Here’s a detailed outline of the processes.

Valves in for repair undergo rigorous inspections to ensure their reliability and safety. During repair at an M&M International ARF, valves undergo thorough disassembly and inspection to assess the condition of each component. Extensive cleaning procedures remove all residues and contaminants. Visual inspection is the next step, providing an initial assessment of the valve's physical condition, including wear, corrosion, and damage. Non-Destructive Testing (NDT) techniques such as magnetic particle inspection and dye penetrant testing are then employed to detect internal flaws or indications that may compromise performance.

During the repair process, other key tasks include replacing seals, springs, and internal parts (when necessary) to prevent leaks and ensure functionality. Internal part replacements can restore proper operation, and damaged threaded connections can be re-machined to specifications.

After repair, valves are reassembled, tested for leaks and performance, and re-certified. Pressure testing is conducted to verify that the valve can withstand the required pressure levels without any leakage, ensuring its integrity under operational conditions. Scheduled preventative maintenance, including routine cleaning after use and proper lubrication, preserves valve integrity and functionality, ensuring reliable and efficient operation.

Choosing to have their M&M International products repaired at an ARF offers customers numerous benefits. You can count on enhanced reliability and minimized downtime with professional, certified repairs. Each repair meets M&M International’s rigorous standards, ensuring top-notch quality and reliability.

The extensive and growing global network of our ARFs also means faster service and support, no matter where you are. Moreover, local expertise at these facilities enhances product lifecycle management, providing invaluable support throughout the lifespan of your product.

Becoming an Authorized Repair Facility partner with M&M International brings significant advantages. Partners benefit from opportunities for business expansion and development by affiliating with a globally recognized brand like M&M International.

M&M International ARFs gain access to comprehensive training and ongoing support, ensuring they maintain high service standards and expertise in their operations. Furthermore, association with such a prestigious global brand enhances their credibility in the industry, fostering trust and confidence among customers and stakeholders alike.

These advantages underscore the value of joining our network of trusted service providers. To illustrate the strength and diversity of our partnerships, please check out the "Partners" page on our website, www.mmvalve.com, for a listing of our ARF partners. These partners exemplify excellence in service and customer care.

Authorized Repair Facilities play a crucial role in upholding M&M International’s commitment to service excellence. By ensuring professional, certified repairs that meet high standards, ARFs contribute directly to the company's overarching strategy of delivering quality, reliable solutions tailored to customer needs.

This program not only enhances service efficiency and reliability but also strengthens M&M International's global reputation as a provider of trusted, customer-focused solutions. ARFs stand as integral partners in maintaining operational excellence and ensuring customer satisfaction across the board.

If you would like to learn more about becoming an M&M International ARF partner, please reach out to us today at sales@mmvalve.com.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

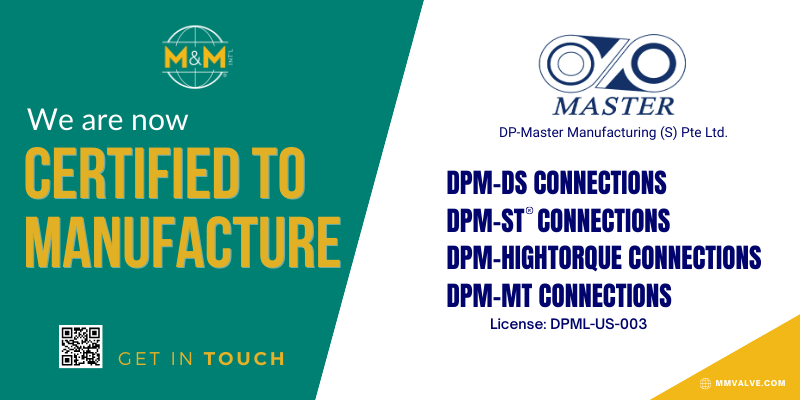

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

M&M International is proud to announce the certification of MAT Energy Services, which has been repairing well control valves for years, as an M&M...

M&M International welcomes Superior Performance, Inc. as its new Authorized Repair Facility in West Texas.

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan