M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Aug 21, 2024 12:44:49 PM

M&M International

Aug 21, 2024 12:44:49 PM

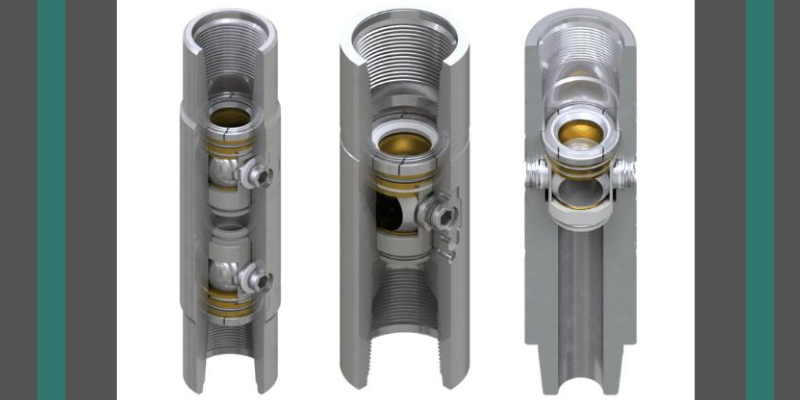

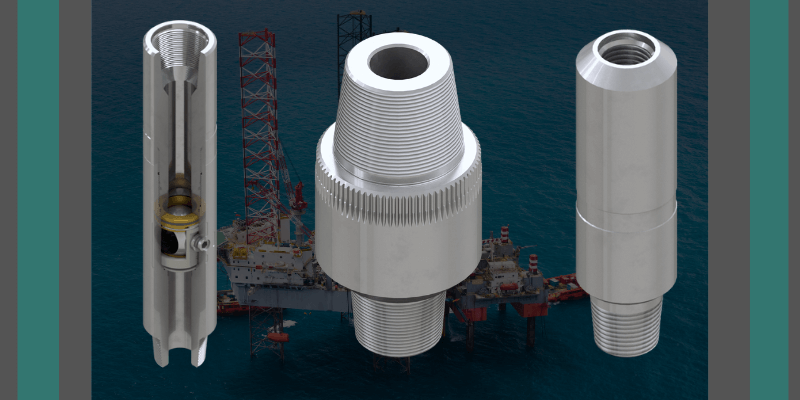

In the oil and gas industry, well control is a critical aspect of ensuring safe and efficient operations. One of the most crucial components in maintaining well control is the safety valve. At M&M International, we understand the importance of reliable safety valves and their role in safeguarding both personnel and equipment. In this blog post, we'll explore the significance of safety valves, the intricacies of valve manufacturing, and explain how they are crucial in well control.

Safety valves are essential devices used in well control to prevent the uncontrolled release of fluids or gases during drilling, production, and other operational phases. They act as a fail-safe mechanism, that can be remotely or manually actuated to seal off well pressure should it reach or threaten to reach undesired and/or unsafe levels. This function is vital in mitigating risks such as blowouts, which can lead to catastrophic events, including fires, explosions, and environmental damage.

M&M International offer's a diverse range of safety valve product configurations tailored to meet the specific needs of the oil and gas industry.

When selecting a valve for well control, it is crucial to first understand your well's specific requirements. This includes assessing the maximum and minimum pressure and temperature conditions your well may experience. One should choose a valve that can reliably handle these extremes without failure.

Additionally, consider the types of fluids involved—such as oil, gas, or water—and their properties, including corrosiveness and abrasiveness, to ensure compatibility with the valve materials. Verify that the materials used in the valve are resistant to potential corrosion and can withstand the temperature ranges that may be encountered in your well operations.

To ensure it meets your operational needs, evaluate the valve's specifications. Check the flow capacity to ensure it can handle the required fluid volumes efficiently. The pressure rating of the valve should align with the possible maximum pressure conditions of your well to prevent any risk of failure. Select a valve size that fits within the existing infrastructure and meets your operational requirements to ensure proper functionality.

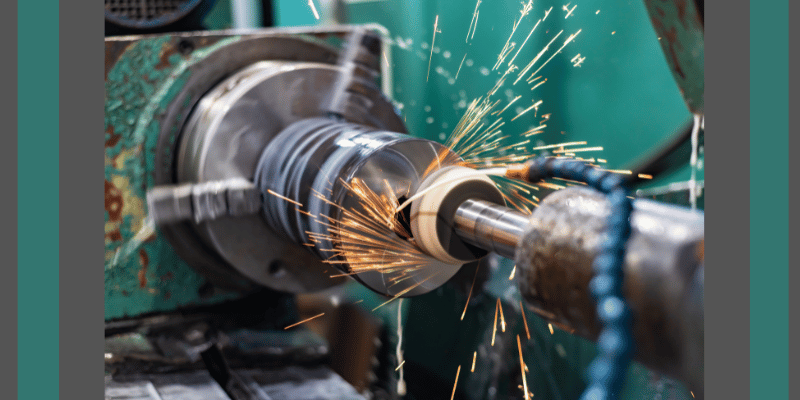

At M&M International, our commitment to quality and safety is reflected in our state-of-the-art valve manufacturing processes. We utilize advanced technologies and adhere to rigorous industry standards to produce safety valves that meet the highest performance criteria.

Each valve is designed, engineered, and manufactured with precision to ensure optimal performance under the most demanding conditions. We select the highest quality materials to construct valves that can withstand extreme pressures and temperatures.

Every valve undergoes comprehensive testing, including pressure and functionality tests, to guarantee reliability and safety. Our stringent testing protocols ensure that our safety valves can consistently perform under extreme conditions, providing our clients with the confidence and security they need for their operations.

By combining precision engineering and manufacturing, superior materials, and rigorous testing, M&M International delivers safety valves that set the benchmark for quality and performance in well control.

Meeting industry standards in the role of safety valves in well control is paramount to ensuring the safety and efficiency of oil and gas operations. Safety valves must adhere to rigorous industry standards such as those set by the American Petroleum Institute (API) and other relevant regulatory bodies. These standards dictate design, manufacturing, testing, and maintenance processes to ensure that safety valves can withstand extreme pressures and temperatures, providing reliable performance under demanding conditions.

At M&M International, we ensure our safety valves meet or exceed these stringent standards. This commitment to quality involves utilizing advanced manufacturing technologies, selecting high-grade materials, and conducting comprehensive testing protocols, including pressure and functionality tests.

By adhering to these industry standards, we guarantee that our safety valves play a crucial role in maintaining well control, preventing blowouts, and protecting both personnel and the environment from potential hazards. Contact us today to get a quote!

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...

With a rich heritage spanning decades, M&M International has been at the forefront of crafting upper and lower top drive valves. Engineered...

Drilling operations have always faced a crucial question: how can efficiency, safety, and performance be maximized simultaneously? The answer lies in...