M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

3 min read

%20(3).png) M&M International

Aug 15, 2024 10:41:55 AM

M&M International

Aug 15, 2024 10:41:55 AM

In the high-stakes world of oil and gas drilling, minimizing downtime is essential for maintaining productivity and ensuring the profitability of operations. Any interruption, no matter how brief, can result in significant financial losses and operational setbacks. This is where the importance of reliable, high-quality equipment becomes evident. Discover how investing in quality can lead to more efficient, uninterrupted operations, ultimately driving success in the competitive oil and gas drilling sector.

1. The Impact of Downtime in Oil and Gas Drilling Operations

3. Importance of Safety Valves in Oil and Gas Drilling

4. Quality Control Inspections: Ensuring Reliability

5. M&M International's Commitment To Quality

Downtime in the oil and gas industry is more than just an inconvenience—it’s a significant financial burden and a risk to operational integrity. The costs associated with downtime can quickly escalate, encompassing direct losses such as halted production and indirect expenses like delayed projects and increased labor costs. In a sector where every second counts, even a brief interruption can result in substantial monetary losses.

Moreover, downtime poses serious risks to safety and environmental sustainability. Unplanned halts can lead to hazardous situations, increasing the likelihood of accidents and spills. The potential for environmental damage not only tarnishes a company's reputation, but also incurs hefty fines and remediation costs.

At M&M International, we are acutely aware of the critical role that high-quality, dependable equipment plays in minimizing downtime. Our commitment to providing robust and durable tools is rooted in the understanding that reliability is the bedrock of continuous operations. Here’s why reliable equipment is indispensable:

Operational Continuity: Reliable equipment ensures that operations run smoothly without unexpected interruptions, allowing for consistent productivity and project completion on schedule.

Safety Assurance: High-quality equipment reduces the risk of malfunctions that can lead to dangerous situations, thereby safeguarding personnel, equipment, and the environment.

Cost Efficiency: Investing in durable and well-maintained equipment minimizes the frequency of repairs and replacements, ultimately leading to cost savings in the long run.

Predictable Performance: With reliable tools, operators can anticipate performance levels and plan activities more effectively, reducing uncertainties and improving overall efficiency.

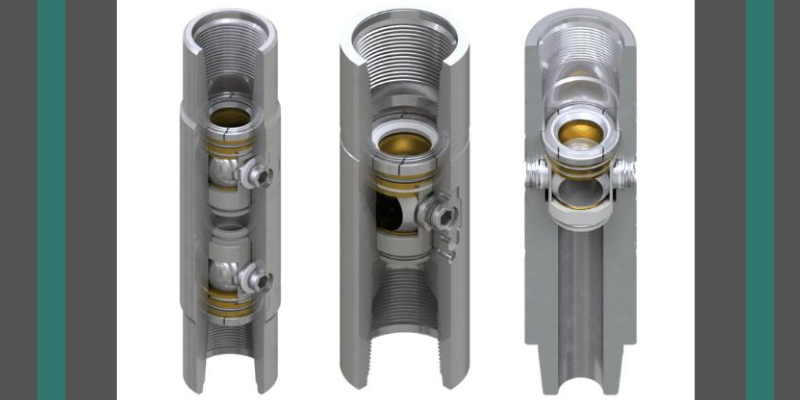

In the demanding environment of oil and gas drilling, safety valves are indispensable components that play a critical role in maintaining safe and efficient operations. These devices are designed to close pressure from a well when it reaches dangerous levels, preventing potential blowouts and catastrophic failures. Safety valves act as the first line of defense against dangerous high-pressure scenarios, ensuring the integrity of the drilling operation and protecting both personnel, equipment, and the environment.

Understanding and prioritizing the function and importance of safety valves is a critical step towards achieving operational excellence in the oil and gas drilling industry. Our safety valves are meticulously engineered to withstand the harsh conditions typical of oil and gas drilling sites. Designed with precision, they offer reliable performance under extreme pressures and temperatures, effectively preventing hazardous incidents.

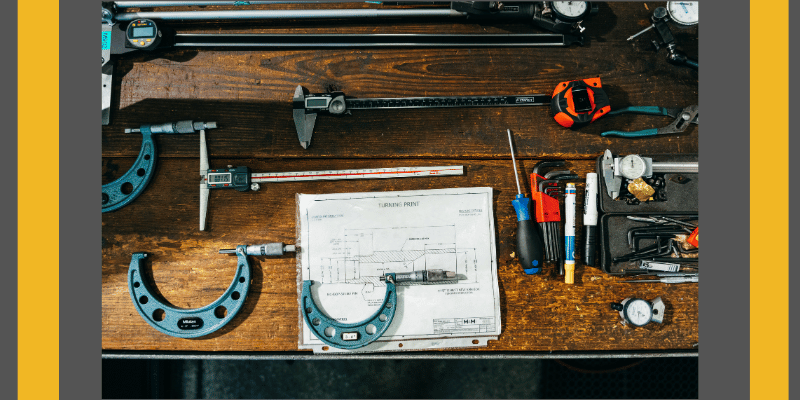

At M&M International, the process of quality control inspections is a cornerstone of our commitment to reliability and excellence. Through rigorous quality control inspections, we meticulously identify and mitigate potential issues before they can impact performance. Our comprehensive approach includes detailed assessments of safety valves and other critical components, ensuring each part meets our high standards.

From precision machining to advanced testing protocols, our mechanical engineering expertise ensures that every piece of equipment can withstand the demanding conditions of oil and gas drilling operations. One of the key quality control measures we implement involves the thorough inspection of safety valves.

These critical components undergo a series of tests to verify their performance under various conditions, ensuring they function flawlessly when needed most. By applying stringent quality control inspections, we catch and address potential defects early, safeguarding the integrity of our products.

With a steadfast commitment to excellence, M&M International manufactures safety valves and accessories that stand up to the rigorous demands of the oil and gas industry, reducing the risk of unexpected downtime. Our dedication to stringent quality control inspections and advanced mechanical engineering practices sets us apart as a leader in dependable equipment for oil and gas drilling operations. Our products do more than enhance operational efficiency; they instill confidence in our clients, equipping them with the reliable tools necessary to thrive in challenging environments.

As we continue to lead with innovation and partner with industry leaders, M&M International invites you to join us in advancing the efficiency and safety of energy production worldwide. Explore our range of solutions and see how we can support your operational goals—because when you succeed, we succeed.

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

With a rich heritage spanning decades, M&M International has been at the forefront of crafting upper and lower top drive valves. Engineered...

At M&M International, our commitment to excellence in mechanical engineering is foundational to our success in delivering high-performance valves....

Operating in the demanding oil and gas exploration field leaves no room for error. Precision isn’t just a requirement—it’s the backbone of safety,...