M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

5 min read

%20(3).png) M&M International

Aug 12, 2024 1:15:30 PM

M&M International

Aug 12, 2024 1:15:30 PM

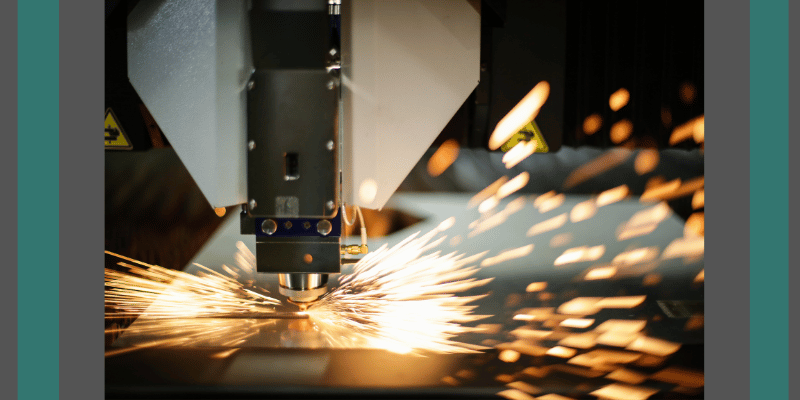

The manufacturing landscape is continuously evolving, and one of the most groundbreaking advancements in recent years is the advent of 3D printing technology. This innovation is particularly significant in the oil and gas industry, where the production of valves is a critical component. In this blog post, we explore how 3D printing is revolutionizing valve manufacturing, bringing efficiency gains, customization possibilities, and potential cost reductions.

3D printing, also known as additive manufacturing, is a technology that creates three-dimensional objects from a digital model by adding material layer by layer. This process contrasts with traditional subtractive manufacturing methods that remove material to shape an object. 3D printing offers the ability to produce complex geometries, customized designs, and rapid prototypes, making it valuable across various industries including oil and gas, aerospace, automotive, healthcare, and more.

In valve manufacturing, it offers several advantages over traditional production methods. Here are some of the types and benefits of 3D Printing for Valves.

In the context of valve manufacturing, 3D printing is particularly advantageous due to its precision and ability to work with high-performance materials. Various types of 3D printing technologies and machines are used to produce valves, each suited to different materials and applications:

Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS): Best for working with stainless steel, titanium, aluminum, and other metal alloys.

Binder Jetting: Used when working with stainless steel, tool steel, Inconel, and other metals.

Electron Beam Melting (EBM): Best suited for titanium, Inconel, and other high-performance alloys.

Laser Powder Bed Fusion (LPBF): Used with stainless steel, aluminum, titanium, and other metals.

These technologies enable the creation of durable, high-precision valve components suitable for demanding applications in various industries.

3D printing offers significant benefits for valve manufacturing, revolutionizing the way these critical components are designed and produced. One of the key advantages is the ability to create highly complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. This allows for the optimization of flow paths and the integration of multiple parts into a single component, reducing assembly time and potential points of failure.

Additionally, 3D printing enables rapid prototyping, which accelerates the design iteration process and reduces time to market. Manufacturers can quickly produce and test different valve designs, ensuring optimal performance before full-scale production.

Customization is another major benefit, as 3D printing allows for the production of valves tailored to specific requirements, whether in terms of size, shape, or material properties. This flexibility is particularly valuable in industries such as oil and gas, aerospace, automotive, and healthcare, where precision and reliability are paramount.

Furthermore, 3D printing can reduce material waste and lower production costs by using only the material needed for each part. Overall, 3D printing enhances the efficiency, innovation, and sustainability of valve manufacturing.

One of the most significant benefits of 3D printing in valve production is the dramatic increase in efficiency. Traditional valve manufacturing involves multiple steps, including sawing, machining, and assembly, each requiring significant time and resources. With 3D printing, these steps can be consolidated into a single process, drastically reducing production time.

For instance, consider a scenario where a custom valve is needed for a specific application in an oil refinery. Using traditional methods, creating this custom valve could take weeks or even months, involving several rounds of prototyping and adjustments. With 3D printing, the same valve can be designed and produced in a matter of days, ensuring faster deployment and less downtime.

Integrating 3D printing into valve production offers a transformative approach to streamlining operations within the oil and gas industry. This technology significantly accelerates the prototyping phase, allowing for faster design iterations and more efficient testing of valve components.

The rapid production capabilities of 3D printing also facilitate the swift creation of replacement parts, reducing downtime and minimizing disruptions to critical operations. Additionally, the ability to manufacture parts on-demand eliminates the need for extensive inventory and reduces lead times for procurement.

This results in a more responsive and agile maintenance and repair process, enhancing overall operational efficiency. By leveraging these benefits, companies can improve their ability to address issues promptly and maintain optimal performance levels across their systems.

Another remarkable advantage of 3D printing in valve manufacturing is the ability to create highly customized components. In the oil and gas industry, valves often need to meet stringent specifications and operate under extreme conditions. 3D printing allows manufacturers to tailor each valve to the exact requirements of its application, ensuring optimal performance and reliability.

Imagine a scenario where a pipeline system requires valves with unique geometries to handle specific fluid dynamics. Traditional manufacturing might struggle to produce these specialized shapes, but 3D printing can easily create complex designs that meet precise engineering specifications. This customization capability leads to better-performing valves and more efficient pipeline systems.

Cost reduction is another critical aspect where 3D printing outshines traditional manufacturing methods. The ability to produce parts on-demand means that companies can significantly reduce inventory costs by eliminating the need for large stocks of pre-manufactured components. This just-in-time production approach minimizes the capital tied up in inventory and reduces storage space requirements. Additionally, 3D printing's material efficiency plays a major role in cost savings.

Traditional manufacturing often involves significant material waste due to subtractive processes, where excess material is removed to shape the final part. In contrast, 3D printing builds parts layer by layer, using only the material necessary for the final product. This additive process drastically reduces raw material usage, leading to lower material costs.

Furthermore, the reduction in waste contributes to a more sustainable manufacturing process, aligning with environmentally conscious business practices and potentially reducing disposal costs. The overall result is a more economical and efficient production system that offers substantial cost advantages over conventional manufacturing techniques.

The future of manufacturing in the oil and gas industry is being shaped by the revolutionary capabilities of 3D printing. By transforming valve production, 3D printing offers unparalleled efficiency gains, customization possibilities, and cost reductions. As this technology continues to advance, we can expect even greater innovations that will further enhance the productivity and sustainability of the oil and gas sector.

For M&M International, embracing 3D printing in valve manufacturing represents an exciting opportunity to stay at the forefront of industry advancements and deliver superior solutions to our clients. Stay tuned as we continue to explore and integrate these cutting-edge technologies into our manufacturing processes. If you have any questions, contact us!

%20(3).png?width=123&height=123&name=_(250%20x%20250%20px)%20(3).png)

M&M International is a family owned and operated original equipment manufacturer in the energy industry. Since its founding in 1980, M&M has become internationally known in the industry for creating and manufacturing the most efficient, reliable, and user-friendly well control valve design in the world, namely, the CANISTER GUARD®.

M&M also manufactures a wide variety of subs, inside blowout preventors (“IBOPs”), swivels, surface test trees, offline cementing valves, and other equipment used during drilling, completion, and production operations, both on land and offshore. In addition to our products, we also offer a full spectrum of manufacturing services and stand ready to build not only our own designs, but the designs brought to us by our customers and partners.

The M&M International Team is committed to solving the most common, and uncommon, problems associated with the well control sector today. We also put forth great effort assisting our customers in solving problems associated with other aspects of the energy industry. We are a dynamic and customer satisfaction-oriented company that is focused on helping its customers improve on multiple levels, not just with their well control needs. No matter what we are doing for the customer, we deliver extraordinary service that is superior to any of our competitors.

Located at 1249 Evangeline Thruway, Broussard, Louisiana 70518

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

Operating in the demanding oil and gas exploration field leaves no room for error. Precision isn’t just a requirement—it’s the backbone of safety,...

Efficient management of stainless raw bar inventory is not just a logistical necessity. It’s the backbone of consistent, high-quality valve production

In the critical field of safety valve manufacturing, precision, traceability, and adherence to rigorous industry standards are paramount. Among the...