M&M International at SPE/IADC 2025 (Stavanger, Norway)

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

4 min read

%20(3).png) M&M International

Jan 7, 2025 7:22:00 PM

M&M International

Jan 7, 2025 7:22:00 PM

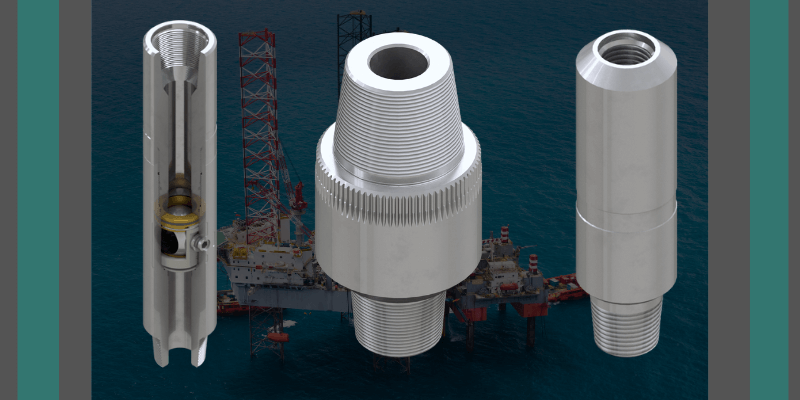

Drilling operations have always faced a crucial question: how can efficiency, safety, and performance be maximized simultaneously? The answer lies in the precise engineering of components seamlessly integrating into the drilling process. Kelly valves, crossover subs, and saver subs are three pivotal tools that revolutionize modern drilling, offering unparalleled benefits that set the stage for operational success.

At M&M International, our focus on innovative valve manufacturing ensures that these critical components exceed industry standards. Let’s explore how these engineering marvels enhance drilling efficiency, safety, and performance while delivering tangible client benefits.

Kelly valves are essential for drilling operations, functioning as robust safety and control mechanisms. These specialized valves are positioned within the drill string and are crucial for maintaining well control, especially during drilling or tripping operations. They act as a critical barrier against blowouts or other well-control issues by enabling the immediate shut-off of drilling fluid flow. Their role extends beyond simple shut-off; kelly valves safeguard operations against unforeseen hazards, ensuring safety and operational efficiency.

The kelly valve’s primary function is to provide a reliable means to shut off the flow of drilling fluids. This efficiency is especially crucial during tripping operations, where time-sensitive decisions impact the project’s timeline and budget. The quick and precise control offered by kelly valves ensures minimal downtime.

Safety is non-negotiable in drilling operations. Kelly valves act as a first line of defense, preventing blowouts by securely controlling fluid flow. Their durable construction and reliable performance minimize risks, even in high-pressure scenarios.

Constructed with high-strength materials, kelly valves are engineered to withstand extreme conditions. Advanced manufacturing processes ensure these valves maintain integrity under significant mechanical stress, offering longevity and reliability in demanding environments.

Crossover subs are critical in connecting various components within the drill string. These tools are designed to bridge differences in thread types and/or sizes between connected parts, ensuring that components work seamlessly together. Their versatility and adaptability make them indispensable in modern drilling.

Crossover subs allow operators to integrate diverse tools, reducing the need for custom fittings or replacements. This capability enhances operational flexibility and saves time and resources in the field. Additionally, their robust construction ensures a secure and leak-proof connection, minimizing the risk of equipment failure or downtime. By facilitating efficient tool compatibility, crossover subs contribute significantly to the success and cost-effectiveness of drilling operations.

The primary function of crossover subs is to connect drill string components with differing thread sizes and/or types. This adaptability allows operators to use diverse tools, reducing the need for custom components and enhancing operational flexibility.

Engineered with precision, crossover subs ensure a secure and leak-proof connection. This seamless integration minimizes wear and tear on other components, ultimately extending the lifespan of the drill string.

Crossover subs reduce the need for specialized equipment by enabling compatibility among various tools. This cost-effective approach translates to significant savings over the lifespan of a drilling operation.

Saver subs are essential in drilling operations, designed to protect more expensive and critical drill string parts, such as kelly spindles, drill pipe connections, and other high-value tools. Positioned at strategic points within the drill string, these sacrificial components absorb the brunt of the wear and tear that occurs from the repeated connection and disconnection of drill string components.

By taking on the bulk of this stress, saver subs help extend the lifespan of the more expensive parts they protect, reducing the need for costly repairs or replacements. This protective function ensures that drilling operations can proceed smoothly without interruption, contributing significantly to operational cost savings and efficiency.

Saver subs absorb the wear and tear caused by repeated connection and disconnection of drill string components. This protection ensures critical tools maintain functionality, reducing maintenance costs and downtime.

One of the standout features of saver subs is their easy replaceability. Designed to be a cost-effective buffer, these components can be swapped without requiring specialized tools or excessive labor.

Precision engineering ensures that saver subs maintain a tight seal and structural integrity even under the most demanding conditions. This reliability enhances the overall performance and safety of the drilling operation.

At M&M International, our commitment to precision valve manufacturing ensures that kelly valves, crossover subs, and saver subs meet the highest quality and performance standards for drilling operations.

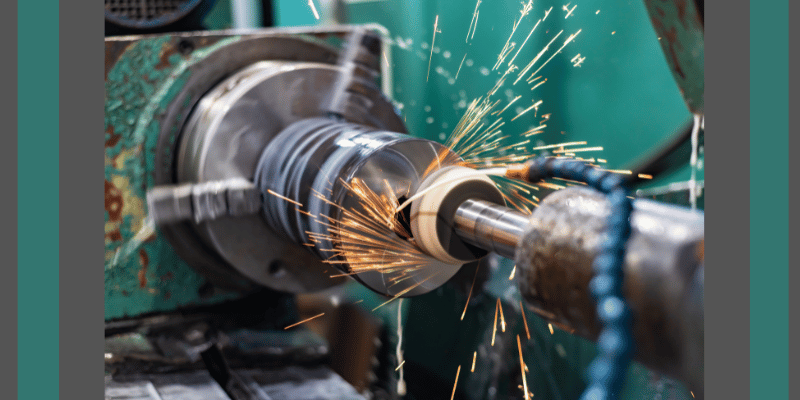

Using only premium-grade materials, our components are designed to endure extreme pressure, temperature, and corrosive environments. This meticulous selection process guarantees durability and safety.

Every kelly valve, crossover, and saver sub undergo comprehensive testing to ensure optimal performance. We leave no stone unturned in validating our products.

Our engineering teams leverage cutting-edge technology to design components that address industry challenges. This commitment to innovation allows us to deliver tools that are not just functional but transformative.

Our clients rely on M&M International for products that enhance their operations. The benefits of our kelly valves, crossover subs, and saver subs extend beyond performance metrics:

The world of drilling is ever evolving. Precision and reliability are paramount and kelly valves, crossover subs, and saver subs stand out as indispensable tools. At M&M International, our dedication to engineering excellence ensures these components deliver unparalleled value, safety, and performance.

Explore how our innovative solutions can transform your operations—Trust M&M International to provide the tools that drive success in the most challenging drilling environments. Contact us today to learn more about our industry-leading valve manufacturing expertise.

M&M International to Attend the 2025 SPE/IADC International Drilling Conference & Exhibition in Stavanger

M&M International Welcomes NEOP, LLC as an Authorized Distribution Partner for the Appalachia Region and Michigan

M&M International is proud to announce an expansion of its DP-Master Manufacturing License with the addition of two cutting-edge connections: ...

In the high-stakes world of oil and gas drilling, operational safety is paramount. Drill Stem Safety Valves play a critical role in ensuring the...

There are various types of subs used in drilling, but one of the most crucial is the crossover sub. Let's examine the significance of this sub and...

Operating in the demanding oil and gas exploration field leaves no room for error. Precision isn’t just a requirement—it’s the backbone of safety,...